The Relevance of Metal Shops: An Extensive Summary of Their Effect On Production

Metal shops are essential to the manufacturing landscape. They transform resources right into components that serve diverse sectors, from automobile to aerospace. Their knowledge in alloy solution and spreading techniques assures the manufacturing of resilient components. The sector deals with obstacles that might improve its future. Comprehending these dynamics exposes real value of foundries in technical and financial contexts. What exists in advance for this crucial field?

The Duty of Metal Foundries in the Production Process

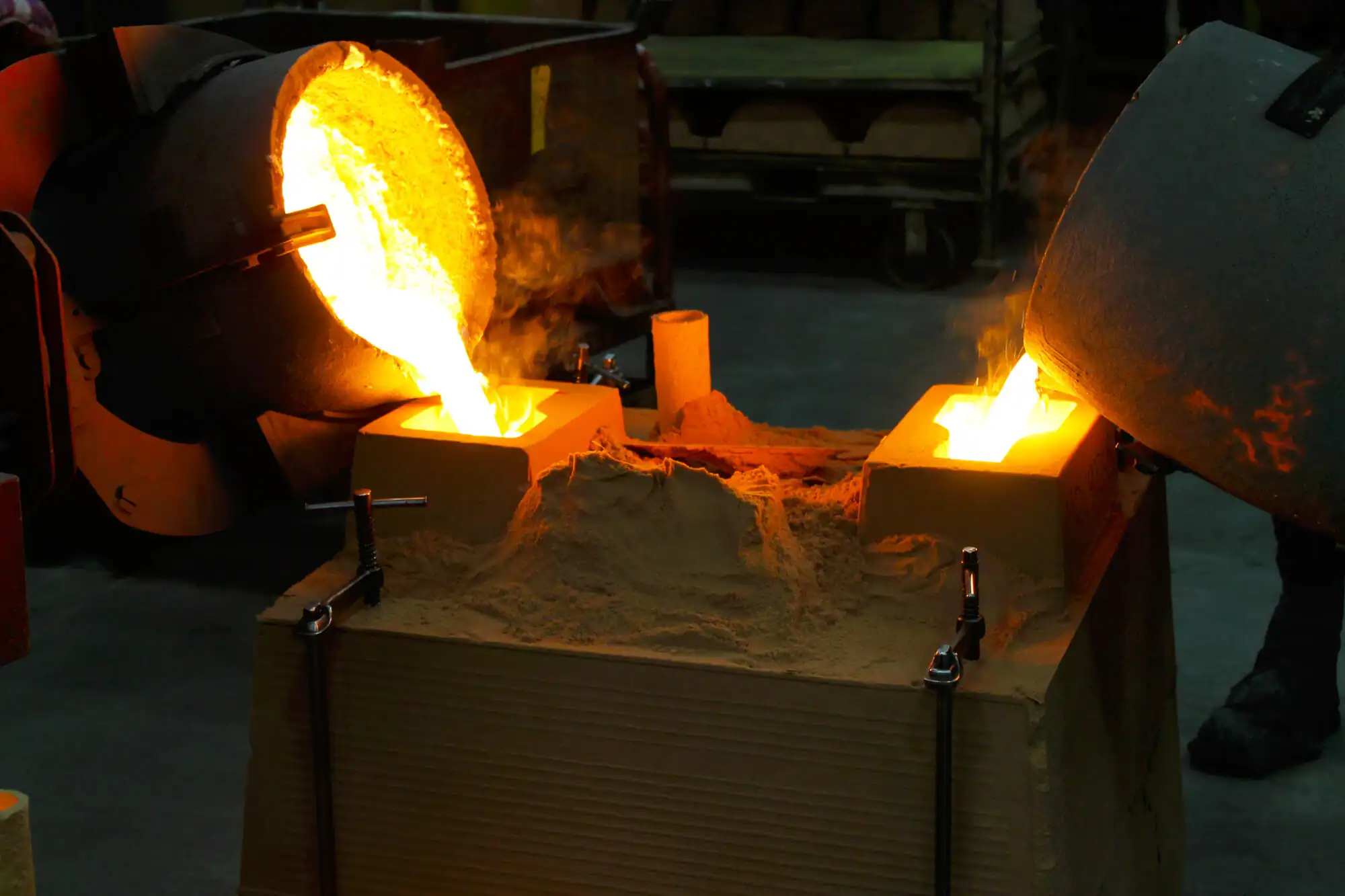

Although often overlooked, metal factories play a vital duty in the manufacturing process by transforming raw metals into usable elements. These facilities concentrate on melting various steels, such as aluminum, iron, and bronze, and pouring them into molds to produce components for varied markets. The process begins with the careful selection of basic materials, making certain that just the best steels are utilized. Once melted, the steel handles the shape of the mold and mildew, strengthening right into components that meet details style and efficiency requirements.

Steel shops add significantly to industries like automotive, aerospace, and building and construction by providing essential parts such as engine blocks, equipments, and architectural assistances. Their proficiency in alloy formulation and spreading strategies allows producers to generate intricate designs while maintaining stamina and resilience. As a result, steel shops not just assist in the production of crucial components however additionally improve the overall effectiveness and performance of modern production.

Enhancing Manufacturing Efficiency Via Advanced Techniques

Steel shops are increasingly taking on sophisticated methods to boost production effectiveness and satisfy the expanding demands of different sectors. The implementation of automation and robotics has streamlined procedures, lowering hands-on labor and increasing accuracy in metal casting operations. Additionally, the combination of computer-aided style (CAD) and simulation software program enables much better preparation and optimization of manufacturing process, decreasing waste and reducing lead times.

Lean producing principles are additionally being employed to eliminate ineffectiveness and boost source usage. Factories are now concentrating on energy-efficient practices, such as making use of waste warm healing systems, which additionally add to cost savings and environmental sustainability. By embracing these advanced methods, steel factories are not only enhancing their functional performance yet likewise improving product top quality, bring about better customer complete satisfaction. As industries proceed to develop, the capability of shops to adjust to these developments will be crucial for preserving competition in the marketplace.

Innovations in Metal Spreading Innovation

As the need for precision and effectiveness in making grows, technologies in metal spreading innovation are transforming the sector landscape. Innovations such as 3D printing and computer-aided layout (CAD) are enabling shops to create complicated geometries with better precision and rate. These methods reduce product waste and decrease preparations, cultivating a more sustainable production procedure.

Smart factory technologies, consisting of the Net of Things (IoT), facilitate real-time surveillance and information evaluation, optimizing production performance and minimizing downtime. Jointly, these advancements are not just enhancing the abilities of steel shops but likewise setting the stage for the future of production, identified by raised dexterity and responsiveness to market needs.

The Economic Impact of Metal Factories on Global and neighborhood Markets

Steel foundries play a crucial duty fit economic landscapes, both locally and globally. They generate significant job creation possibilities and contribute to export and trade, bolstering total financial growth. In addition, foundries sustain regional business environments, fostering synergistic relationships that boost area resilience.

Job Creation Opportunities

Job development in the metal foundry field considerably affects both local and international economic climates. These facilities provide many job opportunity throughout different ability levels, from knowledgeable labor to engineering and administration settings. The need for steel elements in industries such as auto, aerospace, and construction drives the need for a durable labor force. As steel foundries expand, they promote extra job production in ancillary markets, consisting of transportation, logistics, and supply chain management. Furthermore, the financial stability offered by shop work adds to local communities with enhanced spending and investment in framework. On the whole, the steel shop industry's ability to produce work not only enhances individual source of incomes yet also strengthens local growth and resilience, showcasing its important function in economic growth.

Export and Profession Contributions

A significant part of the financial impact produced by foundries originates from their contributions to trade and export. Metal foundries play an important duty in providing components for different markets, including automobile, aerospace, and construction, thus improving a nation's export abilities. this post By generating top quality spreadings and elements, shops enable regional economic situations to contend on an international range. The export of these items not just boosts revenue but likewise promotes international partnerships and trade arrangements. On top of that, shops add to a positive profession balance, which is critical for economic stability. The export activities of metal shops promote innovation and financial investment, eventually reinforcing their relevance in both neighborhood and global markets, driving development and economic durability.

Citizen Business Support Systems

While neighborhood economies usually profit from the existence of metal shops, their impact prolongs past mere task creation. These facilities add significantly to local business support group by fostering a network of providers, service companies, and secondary markets. This interconnected ecological community boosts economic resilience, permitting smaller sized organizations to prosper along with larger shops. Additionally, metal shops typically participate in area initiatives, spending in regional facilities and education, which additionally boosts economic development. On a broader scale, the visibility of factories can draw in investment and talent, strengthening the region's competitive benefit in global markets. Eventually, the economic payments of metal factories not just develop straight work yet additionally grow a helpful atmosphere for varied local business.

Challenges Facing Metal Foundries in the Modern Age

As the steel factory market evolves, it encounters various difficulties that endanger its sustainability and competition. One substantial issue is the raising price of raw products, which directly impacts production costs. International supply chain disruptions further aggravate this problem, making it tough for factories to preserve constant operations. In addition, labor shortages offer a considerable hurdle, as proficient workers become scarce in a rapidly altering technical landscape.

Steel shops must contend with stringent environmental laws that require higher conformity prices and investment in cleaner modern technologies. This shift calls for foundries to adjust promptly, often straining financial sources.

Competition from automated production processes and abroad production includes stress, compeling neighborhood foundries to innovate or risk obsolescence. Addressing these difficulties is important for the market to prosper in a progressively complicated and affordable market atmosphere.

Sustainability Practices in Metal Starting

In Visit Website feedback to the difficulties dealt with by the sector, steel factories are significantly embracing sustainability techniques to improve their operational efficiency and ecological duty. These methods include the application of energy-efficient technologies, such as electrical induction heating systems, which decrease power usage and greenhouse gas exhausts. In addition, many foundries are concentrating on reusing scrap metal, decreasing waste, and using environmentally friendly materials to decrease their ecological footprint.

Water preservation steps are also being prioritized, with systems established to reuse procedure water, consequently minimizing freshwater usage. Furthermore, shops are buying worker training programs to promote lasting methods amongst employees, cultivating his response a society of ecological understanding.

Future Trends in the Metal Foundry Industry

Moving and emerging innovations market demands are positioned to improve the metal foundry industry in the coming years. Enhancing automation, driven by developments in robotics and expert system, is anticipated to enhance manufacturing efficiency and lower labor expenses. Metal Foundry. Furthermore, additive production methods, such as 3D printing, are getting grip, permitting even more facility and personalized metal elements with lowered waste

Sustainability will certainly also play a crucial duty, with shops embracing greener methods to lessen their ecological influence. The industry is most likely to see an increase in the usage of recycled products as raw inputs, aligning with worldwide sustainability goals.

The demand for light-weight and high-performance alloys, especially in the aerospace and vehicle industries, is anticipated to raise. This advancement will certainly require ongoing financial investment in research and growth, making it possible for steel factories to thrive and adjust in an affordable landscape. Generally, these patterns are established to redefine the operational landscape of steel shops.

Frequently Asked Inquiries

What Kinds of Metals Are Commonly Used in Foundries?

Usual steels utilized in foundries include iron, copper, aluminum, and zinc. These materials are favored for their distinct buildings, allowing varied applications in industries such as auto, aerospace, and building and construction, contributing significantly to manufacturing processes.

Just How Do Metal Foundries Guarantee Item Quality and Consistency?

Metal foundries guarantee product high quality and consistency through rigorous high quality control actions, including precise temperature policy, product testing, and adherence to market standards. Routine evaluations and proficient craftsmanship better enhance dependability and harmony in production procedures.

What Security Measures Are Executed in Metal Factories?

Metal shops carry out safety procedures such as personal safety tools, air flow systems, normal security training, and rigorous adherence to safety procedures to reduce threats. These techniques aim to shield employees and keep a risk-free functioning atmosphere.

What Are the Job Opportunities in the Steel Factory Industry?

Career chances in the metal shop industry consist of roles such as foundry workers, high quality control inspectors, engineers, maker drivers, and administration placements. These duties require numerous abilities, offering pathways for advancement and field of expertise within the area.

Just How Do Factories Handle Waste and Recycling of Products?

Shops manage waste and recycling via procedures like recovering sand, melting scrap metal, and making use of by-products for energy. These methods decrease ecological impact while promoting sustainability within the steel spreading industry and boosting resource performance.

Typically neglected, metal foundries play a crucial role in the manufacturing procedure by changing raw metals right into usable components. Metal factories are progressively taking on innovative strategies to enhance production efficiency and meet the growing needs of different markets. Metal shops play an important function in providing elements for various markets, including auto, aerospace, and building and construction, consequently improving a nation's export capacities. In action to the difficulties faced by the sector, steel shops are increasingly embracing sustainability methods to improve their functional efficiency and environmental responsibility. Metal Foundry. Job possibilities in the metal foundry industry consist of duties such as shop employees, top quality control assessors, engineers, maker drivers, and administration settings